The British life sciences company, Genial Genetic Solutions, asked my company to design and programme the control system for their revolutionary new machine, the MultiPrep CellSprint™ for automating the preparation of samples for genetic analysis. The machine automatically and consistently prepares samples of bodily fluids, such as amniotic fluid, freeing scientists and laboratory staff for the more important task of analysing the samples and diagnosing potential diseases.

The samples are presented to the machine in special containers, or buckets, that hold four test tubes. At the heart of the process is a centrifuge for separating any cells in the samples from the liquid. Having centrifuged the samples, the excess liquid above the clump of cells is aspirated (drawnoff) and the test tube is topped up with hypotonic solution, which is a cocktail of three reagents in varying ratios specific to a particular procedure, then centrifuged again. The excess liquid is again aspirated, fixative is added and the cycle repeated, leaving highly concentrated samples that are ready for analysis.

The machine performs a complex sequence of operations that takes between 45 and 60 minutes to complete. It has eight stepper motors driving three pumps for metering the reagents and five axes of motion for the handling operations, plus a servomotor for driving the centrifuge, and twenty-eight valves for controlling delivery of the different reagents to the test tubes.

The Operation

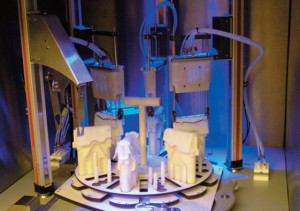

Close-up of samples in the machine.

Up to twelve buckets, each holding four test tubes, are loaded onto a circular tray which is then placed in the machine by a lab technician. The tray sits on a rotary carousel that indexes through twelve discrete positions, driven by a stepper motor, bringing each of the buckets in turn under a pick-and-place unit that lifts them off the tray and loads them into the centrifuge. The centrifuge has positions for six buckets, so the machine processes the six odd-numbered buckets (1, 3, 5, 7, 9 and 11) first, then the even-numbered ones. The centrifuge is driven by a geared servo motor at speeds up to 1,000rpm. Deceleration to standstill is gradual, to avoid disturbing the cells which have settled in the bottom of the

test tubes. It stops in the correct orientation for loading and unloading the buckets.

The servo motor indexes the centrifuge so that each bucket is presented under the loading mechanism in turn. After centrifuging the odd buckets, the machine places them back on the tray and loads the even buckets into the centrifuge. Whilst these are being centrifuged, the rotary carousel indexes each of the odd buckets in turn under the aspiration station. The aspiration head has four nozzles mounted on a vertical in-feed slide driven by a stepper motor, which lowers the nozzles into the test tubes. Each nozzle comprises a pair of cannulas (thin, hollow steel tubes) up which liquid is drawn by a vacuum pump. The pair of cannulas are electrically isolated from each other; when they enter the liquid a circuit is made which activates the aspiration valve for that particular nozzle and the liquid is drawn off from the surface as the head advances.

Once the head reaches a pre-determined depth, it retracts and the rotary carousel indexes the next bucket into the aspiration station. Before the next aspiration cycle, the head moves to a cleaning station where the nozzles are flushed through and cleaned with one of the reagents, to avoid cross- contamination of the samples. Having aspirated the excess liquid, the carousel indexes the bucket under the hypotonic solution dispensing station, which has four pipettes mounted on a vertical in-feed slide driven by a stepper motor, which lowers the pipettes into the test tubes.

The pumps and valves on each reagent circuit operate according to the recipe required for that particular procedure, to dispense the correct cocktail of reagents into the test tubes. The aspiration and dispensing heads are positioned around the carousel such that one bucket is undergoing the dispensing process whilst the bucket following it is undergoing aspiration, which reduces overall processing time and increases throughput. The time for aspiration and dispensing is roughly the same as for centrifuging. When the centrifuge finishes, the even buckets are unloaded and placed on the tray, and the odd buckets are returned to the centrifuge. Whilst the odd buckets go through their second centrifuging cycle, the even buckets go through their first aspiration and dispensing cycle. At the end of this cycle, the buckets are swapped again. The odd buckets go through a second aspiration cycle then through the fixative dispensing cycle, whilst the even buckets go through their second centrifuging cycle. When the centrifuge finishes, the even buckets are returned to the tray and go through a second aspiration cycle then through the fixative dispensing cycle. The samples go through a final centrifuging and aspiration cycle, which leaves them highly concentrated and ready for analysis.

My Contribution:

I helped Genial Genetic Solutions successfully complete their exciting development project to build a working prototype of this versatile and extremely productive piece of laboratory automation equipment.

Genial Genetic Solutions gave me responsibility for:

- Designing and building the control system and wiring up the machine

- Advising on machine layout for ease of manufacture and ergonomics

- Value engineering the prototype machine to come within the budget

- Programming the controller and HMI (human-machine interface) to perform the complex sequences of operations and provide a user-friendly interface

- Supporting the prototype build, commissioning the machine and making it work

Tray holding six buckets sits on the rotary carousel which acts as a cover for the centrifuge whilst in operation.

MultiPrep CellSprint™ is a trademark of Genial Genetic Solutions Ltd

Follow Tim!