This highly innovative project was undertaken for Ridgway Machines Ltd, in Anstey, Leicester, a leading UK manufacturer of taping machines for electrical conductors and large diameter tubes. Ridgway supplied the Taping Machine to a customer in China. The machine is used for wrapping continuous lengths of extruded plastic pipe with steel tape.

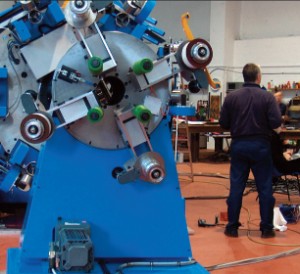

Taping head 1 (background) and taping head 2 (foreground) in operation in the customer’s factory

The pipe is made in various diameters from 50mm to 150mm (2”-6”) bore, in lengths up to 1km. It is spirally wound with either two or four layers of steel tape, with each layer comprising two, three, four or six tapes, to prevent the pipe bursting under high internal pressure. The pipe is finally wrapped with plastic tape. This form of construction has the benefit that the finished pipes are flexible and can be wound onto drums for transport to site.

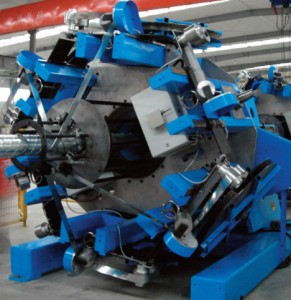

The pipe is fed through taping heads 1 and 2, each of which applies a layer of steel tape, then through taping head 3 (out of shot to the left) which applies the final layer of plastic tape. The pipe is drawn axially through the taping machine by a caterpillar.

Taping head 3

Taping heads 1 and 2 each comprise a large rotating assembly, driven by a geared servomotor, which carries six equi-spaced tape dispensers. One head rotates clockwise whilst the other rotates counter-clockwise. Each steel tape is fed from a reel through a closed-loop, servo-controlled tensioning system, then over a final roller which turns the tape to wrap it onto the pipe at the required angle. Roller angle is set manually by the operator prior to machine operation. Tape tension is also variable according to pipe diameter, tape width and wrap angle. Tape tension is continuously controlled with a maximum 1kN (100kgf) tension in each tape. Either two, three, four or six steel tapes can be applied simultaneously, which ensures that the forces on the pipe remain balanced.

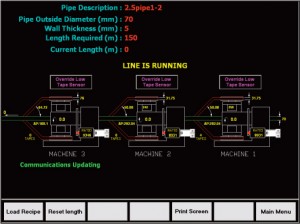

User-friendly operator interface

Taping head 3 applies the final layer of plastic tape. It is driven by a geared servomotor to control its rotational speed. It has four tape spindles. Either two or four plastic tapes can be applied simultaneously. Tape tension is governed by a simple friction brake on each spindle. The plastic tapes overlap to completely cover the finished pipe. The pipe to be wrapped is drawn axially through the machine by a servo-controlled caterpillar located after taping head 3.

The rotational speed of all three taping heads is synchronised with the caterpillar speed to achieve the required wrap angle. The settings, or recipe, for each product are worked out by a PC. Rotational speed of the taping heads and tension of the steel tapes are downloaded to the machine where they are controlled automatically. Because of the difficulty of taking so many power and control signals onto the rotating heads via conventional sliprings, taping heads 1 and 2 use wireless communication between the PC and a local PLC mounted on each head, which distributes the tension settings via a CAN bus link to the six tension control systems which are also mounted on the head. Consequently, only the 580VDC bus for powering the six servo drives plus an earth connection is fed to the rotating assembly via three sliprings. The 24VDC for the PLC and other low-voltage circuits on each head is generated locally from the 580VDC bus.

My company provided Ridgway Machines Ltd with the expertise and commitment necessary to ensure this major capital project was successfully completed and the machine handed over to their customer on time and within budget.

I was given full responsibility for:

- Designing and building all electrical and control systems

- Specifying and supplying the Lenze geared servomotors and drives

- Wiring and testing all electrical and control systems

- Writing the software for generating the product recipes and creating a user-friendly operator interface

- Implementing a robust wireless communication system between the machine and the PC which generates the settings

- Commissioning the machine in Ridgway’s Anstey factory

- Providing all technical literature including the operating manual and training Ridgway’s staff

- Commissioning and testing the machine on site in China to achieve full acceptance on time and within budget

Follow Tim!